|

The Brick Directory Words and Blog

|

|

|

|

|

|

For centuries bricks were moulded by hand in wooden moulds. These were four sided and rectangular in shape with no base or lid. Moulds were placed either directly on the ground or on a roughly made brickmakers table. Bricks made on the ground are generally pre 19th cent. They were known as 'place' bricks and often contain grass impressions. From the 19th cent rectangular block of wood, smaller than the mould dimensions, would be screwed on the table which created the brick's 'frog'. Sometimes letters were carved in the frog to identify the brickyard owner. With the advent of steam power brickmaking became mechanized wherever volume justified it. Steam driven extrusion plants with nine overhead wire cutters produced ten bricks every few minutes.One of the oldest methods of firing is by clamp. A clamp is a temporary construction of unfired or green bricks which is dismantled after firing and could be erected near the clay source. Clamps varied from yard to yard but there were general rules which most followed. The floor had to be level and was made of burnt brick. Channels were often made in the floor and filled with fuel, usually breeze (crushed coke) but any fuel would suffice and wood, furze, charcoal were also used. Next came three or four layers of green bricks which were placed on edge and then another layer of fuel was added. After this, green bricks were packed closely together to a height of 14 or 15 feet. The bricks were 'dished' or tilted inward to prevent injury to workmen during firing. Sometimes the outside was sealed with wet pug. Most clamp bricks had a small percentage of breeze added to the clay during manufacture. This helped to 'self fire' them and ensured that a good temperature was reached. Clamps contained 30,000 to 150,000 bricks. An average size would take two or three weeks to burn out, although larger ones could take as much as ten or twelve weeks. Updraught kilns may be as old as clamps. These were known as Scotch kilns and were permanent structures with one or more firing chambers.The kilns were built of burnt brick. Flues ran under the perforated floor from one end to the other. Green bricks were stacked on the chamber floor with small gaps between them to allow the heat to circulate. The open top was covered with old burnt bricks and turf or pug to help conserve the heat and prevent draughts that would cause uneven firing. The kilns had to be stoked regularly day and night for at least three or four days. It was quite common to see flames rising from the top of these kilns when firing. The death knell sounded for many small yards in 1939 when Blackout Regulations were brought into force. A later development came to be known as a Suffolk kiln. These were fired on the same principle but smaller and set into a bank. One reason for this was to provide ease of access for loading or setting, another was for insulation. The downdraught kiln was far more efficient than the Scotch or Suffolk. Firing was much easier to control. They were often circular in structure with about eight fire holes. Inside the fireholes were baffles or 'bag' of firebricks. It had a domed roof and a perforated floor under which ran a flue leading to the chimney stack. The circular or 'beehive' kiln had a capacity of about 12,000 green bricks. Coal was lit inside the firehole grates and hot gases were directed upward from the baffles and then downwards from the underside of the dome and through the stacked bricks by the draught from the chimney. Altogether it took fourteen days or so to operate, with two days for loading or setting, three days for 'curing', two days for heating to full temperature, one day at full heat, then another three or four days to cool down and a further day to unload or draw.

|

|

|

|

|

|

|

|

|

|

US brick manufacturer, Boral, has released a white paper entitled "Building With Brick: Sustainable and Energy Efficient: A White Paper on Performance Benefits of One of Man's Oldest Building Materials." The paper cites a 4000-year old arch in the Middle East made of brick that still stands today. "All too often, newly invented materials are not only disproportionately expensive, but also lack a time-tested track record that can provide reassurance about their expected performance,” the paper read. Brick’s durability - it's not compromised by decay- contributes to its overall long life with little maintenance. “In fact, because of its durability, the US National Institute for Standards and Technology has rated brick masonry as having a 100-year lifespan,” the report read. By all environmental impact standards, brick is one of the best choices for sustainable eco-friendly construction. Why? 'The efficiency of the manufacturing process, use of alternative energy sources, recycled content, minimized waste and efficiency of transportation because clay and shale used to make brick can be found almost everywhere in the world and they are easily removed from the ground without the damaging effects that accompany the mining of more elusive resources,' the report stated.

One of the notable qualities of brick is that very little waste is produced in the manufacturing and building process because the materials are inherently recyclable “A kilo of clay material yields almost a kilo of brick," states the report. "Any materials that are left over after one run of bricks has been fired can simply be re-mixed into the next run.” Additionally, leftover brick material on the construction site can be recycled in a number of ways, be it crushed for landscaping, reused for other projects or added to concrete aggregate

|

|

|

|

|

|

|

|

Bangladeshi Brick man beheaded to redden bricks Fortune teller calls for human sacrifice

By Mary Papenfuss

Posted Mar 22, 2010 10 3:17 AM CDT

(Newser) – A Bangladeshi man was beheaded in a bizarre ritual to improve a local brick business. When owners became concerned that bricks in a northern village were losing their sought-after reddish hue, a fortune teller encouraged a human sacrifice. Four laborers, following owners' orders, killed a 26-year-old fellow worker and baked his head in a kiln in an effort to redden the bricks. The workers have been busted and police are searching for the owners and fortune teller, reports the Daily Telegraph.

|

|

|

|

|

|

|

|

New method to make Strong Straw bricks By Rob Quinn

Posted Mar 15, 2010 3:16 AM CDT

New method may make it possible to build bricks from straw(Newser) – Spider silk is yielding secrets that could pave the way for incredibly strong building materials, researchers say. MIT scientists found that the silk uses a unique crystal structure that makes it both strong and able to bend without breaking. They believe it is possible to copy that structure to turn ordinary materials like wood or straw into flexible and strong "super-materials," the Telegraph reports. Researchers found that nanocrystals 3 millionths of a millimeter across turned the inherently weak building blocks of spider silk into a material that is, pound for pound, stronger and less brittle than steel. They believe applying the same process to carbon-based building elements will create even stronger materials, potentially revolutionizing the whole field of synthetic materials.

|

|

|

|

|

|

|

|

Those black plastic bricks called VHS tapes The era of VHS is officially over

By Katherine Thompson

Posted Dec 22, 08 9:57 AM CST

(Newser) – Remember those black plastic bricks you used to pop into your entertainment system to watch movies? The nostalgic might want to snap a few digital photos, because tapes won't be with us for much longer now that the last VHS supplier has made his final shipment. The LA Times rewinds the history of a format film critic Leonard Maltin recalls as a "sea change." Videocassettes changed what Americans expected from entertainment, allowing people to choose what they wanted to see and then watch it at home, not to mention recording onto blank tapes. But thanks to DVDs and, increasingly, Blu-ray discs, the last VCRs are on shelves now. Says the last supplier standing: "I'm not sure a lot of people are going to miss VHS, but it's been good to us

|

|

|

|

|

|

|

|

June 9 2009 (Newser) – A Mexican surfer off a California beach was busted for trying to smuggle 24 pounds of pot on his board, reports the Los Angeles Times. When suspicious cops on the beach close to the Mexican border ordered the surfer to come ashore, he heaved a duffel bag into the water. It later washed up, packed with pot bricks worth $74,000, according to law enforcement authorities.

|

|

|

|

|

|

|

|

Sydney, Mar 23, 2010 (ABN Newswire) - Brickworks Limited (ASX:BKW) announce, Australia's leading brick company Austral Bricks(TM), today unveiled Australia's largest tribute to US President, Barack Obama, at Horsley Park on the M7, despite the postponement of his visit. Austral Bricks(TM) went ahead with the 100 square metre construction of the mural in the lead-up to the visit and following the postponement was announced, added the sign "Where the bloody hell are ya?" The wall will be still in place in June, the next scheduled date of the president's much anticipated visit. More than 6,000 glazed bricks were laid over a five day period by J&M Langon Bricklayers and features Austral Bricks(TM) Burlesque(R) and Dynasty(R) ranges. Austral Bricks' national marketing manager, Brett Ward said, "We decided to finish the construction of the wall and the sign with our tongues firmly in our cheeks. We are using Aussie humour as a token of the friendship between our two countries and commemorate the 70th anniversary of our alliance. "We hope our humour is taken the right way by our friends in the US and we will take down the sign as soon as the president steps foot on our shores mid-year", he added."The Brick Art(TM) mural demonstrates the versatility and contemporary nature of what can be achieved with bricks. Austral Bricks is excited about the opportunities that Brick Art(TM) can play in the creation of unique and interesting murals for architects and designers", said Mr Mark Ellenor, NSW General Manager of Austral Bricks.The Barack Obama wall is the latest Brick Art(TM) mural by the company, following on from the Michael Jackson Tribute that was built in September last year. The glazed bricks used in the mural are in colours not normally associated with bricks, including green, white, blue, leather and black from both the Burlesque(R) and Dynasty(R) ranges. Seven of the 10 available brick colours were used to create the impressive art piece.

|

|

|

|

|

|

|

|

|

|

Brickfilms.com site is dedicated to brickfilming - making stop motion animation with LEGO or other brick like elements. Might try it with clay bricks.

|

|

|

|

|

|

|

|

Madonna To Lay Bricks Of New Malawi School

2:31pm UK, Monday April 05, 2010 Hazel Tyldesley, Sky News Online

Madonna has arrived in Malawi to lay the first brickof a new school funded by her charity, which supports poverty-stricken children in the southern African country. Madonna and her adopted children during a visit to Malawi last year.The Raising Malawi Academy for Girls promises to be a family and support centre, allowing female students to attend regular classes as well as giving them access to medical care and regular meals."The Academy will be much more than just a school — in a country where one million children have been orphaned due to Aids, the Academy will educate, protect, and empower young girls," the charity said.

Madonna will be joined by economist Jeffrey Sachs, a development affairs expert who recently entered the debate over the so-called Robin Hood tax, saying it could help boost aid to Africa.The first item on the pop singer's itinerary in Malawi is a trip to a UN community initiative called the Millennium Village, which promotes sustainable development. Madonna has donated millions of pounds towards projects in Malawi and has also adopted two children from the impoverished nation.She won a court battle that had initially blocked her adoption of toddler Mercy James last year, but met criticism from children's charities that suggested the girl could be better cared for in her home country.The singer's £10m centre, located on the outskirts of the country's capital Lilongwe is set to open in 2011.

|

|

|

|

|

|

|

|

|

|

New Technology for Brick Production in Vietnam using coal tailings

April 11th 2010 Vietnam Business News

In order to conserve resources, reduce environmental pollution, create jobs and contribute to the coal industry, producing bricks from coal tailings is being utilized in many coal factories.According to the statistics, every year millions of coal-tailings are thrown into landfills. Coal tailings contain approximately five to eight percent of usable coal, therefore, throwing away coal-tailings is wasteful and leads to illegal coal exploitation at landfill sites. This reality has forced the coal industry to find another way to deal with coal-tailings.

In addition, using clay to produce bricks has been known to destroy agricultural soil and harm the environment. Every year, there are 24 billion bricks needed in the construction industry. To lay these bricks, 36 million cu.m of soil is used, which is equal to 1,800 ha of cultivated land. Exhaust fumes from bricks contain numerous toxic substances, which are extremely harmful to the environment and to people’s health.

After discovering that coal-tailings’ chemical components were similar to that’s of the clay, scientists discovered the technology to make brick from coal-tailings. The technology has been used in many countries. In Vietnam, the project to use coal-tailings to produce bricks has been successfully implemented by the Institute of Mining Science and Technology (under Vietnam National Coal Mineral Industry Group).

Initial success has urged the scientists at the Institute of Mining Science and Technology to apply the technology to produce more than 23,000 bricks from coal-tailings at the Cua Ong and Hon Gai Coal Factories. Nguyen Quoc Thinh from the Institute of Mining Science and Technology said that coal-tailings can be adequately used to produce bricks, which can be used in the construction industry. Coal-tailing bricks are similar to clay bricks in terms of their physical qualities and design.

|

|

|

|

|

|

|

|

21 February 2010 7000-year-old bricks discovered in China

Bricks dating back 5,000 to 7,000 years have been unearthed in northwest China's Shaanxi Province, adding between 1,000 to 2,000 years onto Chinese brick-making history, archaeologists claimed. "The five calcined bricks were unearthed from a site of the Yangshao Culture Period dating 5,000 to 7,000 years ago. Previously, the oldest known bricks in the country were more than 4,000 years old," Shaanxi Provincial Institute of Archaeology researcher Yang Yachang said. Only parts of the bricks, including three red ones and two gray ones, have been recovered, Yang said.

Yangshao Culture is a Neolithic culture that flourished along the Yellow River, which runs across China from west to east. The culture was named after Yangshao, the name of the first village discovered of the culture, in 1921 in central China's Henan Province. Archaeologists used to believe the ceramics were applied to architecture in the Shang Dynasty (1600 BCE-1100 BCE), which had been proved wrong by the new discovery, Yang said.

The smooth surface and rough surface of most well preserved red bricks are vertical to each other, and the rough surface was designed to be stuck to other materials, Yang said. "It is still unknown whether the bricks were in a square or rectangle shape as none of them are complete," he said.

The site, covering an area of more than 200,000 square meters, was to be cut through by a new highway, said Shao Jing, assistant researcher of the institute. The salvage excavation was launched in August 2009. As of February, more than 2,300 square meters had been excavated, Shao added. More than 150 sites, including houses, ash pits, ash grooves and kilns, had been found in the area, Shao said. "The bricks were all discovered in ash pits, which were garbage containers for the ancient people. For the modern archaeologist, these garbage containers are treasure troves of artifacts," she said.

The world's oldest unearthed bricks date back 8,000 to 10,000 years. They were discovered in Middle East and they were adobes which had not been calcined. Thus, the brick-making history of human kind should be about 10,000 years, Yang Yachang said.

Source: CRIemglish (20 February 2010) http://www.stonepages.com/news/archives/003731.html

|

|

|

|

|

|

|

|

|

|

Bangladesh Adopts Green Brick Kiln Technology

Vamban News 5th April 2010 Dhaka,

– In an effort to reduce carbon emission, Bangladesh is looking at smokeless brick making technology to replace the over 150-year-old traditional method in the country. The new technology has been introduced by the UNDP as part of its project ‘Improving Kiln Efficiency in the ’Brick Making Industry.

The UNDP, which started its pilot project in 2006, will contribute $25 million in the next five years for 15 new projects in the country. ‘The innovative technology that is being used to replace the existing 150-year-old system will simply make the brick making industry so efficient that when this is replicated across Bangladesh we will have huge benefits for both the people and the global environment,’ Stefan Priesner, UNDP’s Country Director, said Sunday. UNDP said that the new system could reduce production costs, improve product quality, lower local pollution and, most importantly, reduce greenhouse gas emissions, Xinhua reported. According to UNDP, brick making is one of the largest sources of greenhouse gas emissions in Bangladesh which produces around 6.0 million tonnes of carbon dioxide annually.

High carbon emission level is caused by the outdated technology and substandard fuels such as high sulphur coal, tires and wood energy in kilns, it said, adding that in Bangladesh it takes about 23 tonnes of coal to produce 100,000 bricks whereas in other country it takes only 7.8 to 8 tonnes.

‘The traditional technologies of manufacturing bricks are heavily polluting the environment and in light of the economic growth in Bangladesh there is a huge pressure to manufacture more and more bricks,’ Priesner added.

|

|

|

|

|

|

|

|

by Stephanie sd249707@ohio.edu March 1st 2010

Bare on the Bricks was not a normal fundraising event. If you were anywhere near Court Street, a5hens county in the US on Saturday at noon, you know that. Hundreds of people ran down the busy street in barely anything for a great cause. The event's overall goal was to raise funds and donations of clothes for local Athens clothing banks and the relief efforts in Haiti.

|

|

|

|

|

|

A seven-year-old boy, Roman, sorts bricks at the Sadat brick factory in Kabul where he works every day from 8am to 5pm. Child labour is common in Afghanistan's brick factories where adult workers, desperate to make more money, enlist their children to help with some of the easier jobs.

|

|

|

|

|

|

|

|

|

|

Stone is a material of variety, nuance and unrivalled durability. Used appropriately and with regard to its nature it can enhance the architectural style of a building and last thousands of years. Geological Consultant, Francis Dimes of www.BuildingConservation.com outlines the geological characteristics of the material and the principles of its selection for use in conservation and restoration work

Often considered the aristocrat of building materials, stone is arguably the traditional building material of Great Britain. Stonehenge, of a quartzitic sandstone known as sarsen, dates back to about 1800 BC, a lasting testament to its durability. Yet this was a relatively late arrival compared with the magnificent limestone temples of Malta which date back to before 4000 BC, or the stone houses near Jericho, constructed in about 6000 BC.

Any rock, anywhere, has been used for building if only on a restricted local scale. A study of the geological map of Great Britain shows that the country has a great variety of rocks. But not every rock may be used successfully. Thought must be given to its weathering properties and to its nature, which may allow the rock to be worked to a fine surface and detail. It follows that some knowledge of the local geology will be of help in understanding the relationship of a building, the country in which it stands and the stone of which it is built.

Any stone can be placed geologically (and thus scientifically) into one of three groups. Only when the nature of the rocks in these groups is known can the stone be properly used.

Igneous rocks are those which cooled and consolidated from a fluid melt (magma) of rock material. The magma may have cooled quickly to give fine-grained rocks or slowly, to produce coarse-grained crystalline rocks. The nature will depend also on their chemical composition.

Many have been found in Great Britain, but only one - granite - has been used on any scale. South-West England and Scotland are the great granite producing areas for building.

Sedimentary rocks were originally deposits of sediment (the eroded material from pre-existing rocks) laid down, mostly, on old sea-floors. When compacted and cemented, sedimentary rocks result. Their composition depends on the nature of the original sediment, but only sandstones (composed of quartz grains) and limestones (chiefly of calcium carbonate) have been used on any scale. In general terms, limestone predominates in southern Britain and sandstone in the north, but some limestones such as Portland stone have been used ubiquitously; and some sandstones, for example York stone are widely used especially for paving.

Metamorphic rocks result from the modification of pre-existing rocks by heat, pressure or both. The one which has been most widely used in Britain is slate. Other indigenous metamorphic rocks have been little used. Slate is found chiefly in Scotland, the Lake District, North Wales and Cornwall.

There are constraints inherent in stone which demand that the material is properly used in accordance with its unique characteristics. Igneous rocks may contain minerals which on exposure to the atmosphere may break down with consequent damage to the stone. Rising salts, also, may cause spalling. Of prime importance with sedimentary rocks is the placing of the bedding plane so that it is at right angles to the thrust imposed upon it. Metamorphic rocks may have deleterious (harmful) minerals present. The greatest restraint in the use of stone is that of the jointing. All rocks are jointed and the size of a block that can be wrought from a quarry is controlled by joints.

Such constraints are minor compared with the benefits: Stone from all these groups, whether used in classical idiom or in contemporary form, will have a durability other materials cannot match, provided it is properly chosen and properly used.

STONE FOR CONSERVATION AND RESTORATION WORK

The first requirement when a stone building is considered for conservation or restoration is to determine the nature of the stone. Many historic buildings will have archival records which should be scanned for references to the source. Where that does not produce any answers a geologist should be consulted to determine the nature of the stone. The next stage, the determination of the 'provenance', the source of the stone, may be much more difficult. Again it is best referred to a geologist with specialist knowledge of the geology of stone for building and decoration.

Once the provenance is established (which may not always be possible), a search of the area for still working quarries then follows. Those quarries in Great Britain known to be producing dimensional stone are listed in The Natural Stone Directory (see Recommended Reading). If the stone is still available, can it be obtained within the time-frame for restoration?; and can it be obtained in suitable sizes? It must also be recognised that stone from a present day quarry, whilst geologically the same, may in fact present a slightly different appearance from stone quarried in the past. Nevertheless, to preserve the integrity of the building, the same geological stone is always to be preferred.

However, it is not always possible to find the stone required. In that event a geologically appropriate stone should be sought, and the re-use of original or reclaimed stone should be considered. Although many masons object to 'second-hand' stone, there appears to be no scientific reasons why the material should not be re-used, provided that bedding and other criteria are observed.

The matching of stone from a provenance other than the original is a specialist task. Again, advice should be sought from geologists with experience in this field. It may be necessary at this stage, for thin-sections to be cut for microscopical study, or for X-ray diffraction techniques to be used. Guidance will be given by the specialist.

|

|

|

|

|

|

|

|

|

|

“Chinese companies are making high quality and reasonably priced brick production equipment that are able to meet competition,” Eugeniy KOLESOV, the General Director of Optim Consult Company which joins 12 Chinese Trade Associations, believes. “Though most Chinese equipment is not of popular brand (as many German and Italian goods), the goods turnover with China is obviously growing,” he adds.

“The Chinese brickindustry is developing rapidly; and on the other hand there is a surge of interest in housing development in Russia, besides, lots of projects such as the World Student Games in Tatarstan in 2013 are being implemented. All this creates favorable conditions for the effective cooperation,” Yang ZHISING, the representative of the Chinese Machine Building Association says. “The brick production equipment is in great demand currently and the Chinese companies should get ready to penetrate the Russian market more actively,” the Chinese expert thinks.

“The customers will take more interest in the Chinese building goods and mostly the building equipment will be in demand but not the finished product,” Jung ZHINSHEN, the Deputy Secretary of the Chinese Building Materials Dealers Association, supposes. “In fact, it is much cheaper for our customers to purchase some equipment and make the building materials themselves then to buy the ready-made bricks in China,” he says.

|

|

|

|

|

|

|

|

|

How to match your bricks? First and foremost, bricks are made from clay, and the clay deposit that the brick came from can become depleted and / or the characteristics of the clay may change as the quarry is extended. Alternatively, the brick company the original bricks came from may have gone out of business, or the brick itself may have gone out of style. Brick styles change over time.

It is possible that you may get lucky and find perfectly matching bricks at your local brick merchant. The chances are the task will be a bit more difficult though. Unfortunately, there is no national database of brick colors and textures, although www.brickdirectory.co.uk goes some of the way, but that does not mean that you have to settle for mis-matched bricks.

The first thing that you should do is take some high resolution pictures of the original bricks, as matching from memory is impossible. You should E mail copies of these photos to brickmakers and specialist brick merchantin your area. Try to remember what year you bought the original bricks, and who you bought them from, as the more information you give the brick merchants, the better the chance of them being able to help you. A always let the brick people know the dimensions as Imperial size bricks typically 73mm depth may not be readily available but some handmade brick companies should be able to make them for you

If no-one can find you an exact match of your bricks, then find ones that at least match the color. Finding bricks that are a very close color match is definitely possible with a little looking around. Matching bricks by color is much preferable to matching bricks by texture. You can see texture differences when you stand close to a brick surface, but rarely can you see differences when you stand back 50 or 100 feet. Color mis-matches stand out from any distance.

Once you have found some potential matches, get some samples and take them back to your home for a proper evaluation. Then, be sure to stand back at least 10 feet when judging the quality of the match, as your eyes can sometimes play tricks on you when you look at the bricks up close. Ask a few other people for their opinions on which is the best match, and note down their answers.Remember its not just the bricks you’re hoping to match but also the mortar, texture colour and pointing

|

|

|

|

|

|

|

What is a Brick Workout? A brickworkout is when you do one workout immediately after another. For example, you could do a swim followed by a bike or a bike followed by a run. There is no special way you have to do a brick workout.

|

|

|

|

|

|

|

Brick wall collapse. See video by clicking on this link.TORONTO — Red bricks, black boards and strips of pink insulation blended in a massive pile of rubble near Yonge Street in Toronto on Friday after the facade of a building collapsed over the lunch hour

Read it on Global News: Brick wall topples on Toronto's Yonge Street

|

|

|

|

|

|

|

Villagers steal Russian church — brick by brick

Dismantling, sale of building to local businessman a 'grave sin,' says priest

MOSCOW - Wanted: One missing Russian church. Last seen in July. Reward for its return. Orthodox officials in a central Russian region say an abandoned church building that was to be put back into use has been stolen by local villagers.

Orthodox priest Vitaly of the Ivanovo-Voskresenskaya diocese said officials last saw the two-story Church of Resurrection intact in late July. Sometime in early October, however, people from the nearby village of Komarovo, northeast of Moscow, dismantled the building, he said.

Villagers apparently sold it to a local businessman, one ruble (about 4 cents) per brick, Vitaly said. Orthodox priests use only one name.

"Of course, this is blasphemy," he said. "These people have to realize they committed a grave sin."

Vitaly said police were investigating the theft.

The 200-year-old building, which no longer had its icons and other religious valuables, was a school for disabled children during the Soviet era before it was closed down in 1998 and turned over to the church.

Vitaly said the diocese was thinking of reopening it for services.

The Orthodox church has experienced a major resurgence in Russia and has restored or built thousands of churches.

In poorer, rural regions, vandals or petty thieves regularly steal gilded icons or donations from churches and sell them for alcohol or drugs.

|

|

|

|

|

|

|

Robot Builds Brick Wall In New York City

ScienceDaily (2009-10-26) -- A robot is currently building a looping brick wall right in the middle of New York City. Over a period of three weeks, passers-by can watch the "Pike Loop" installation in the making on a traffic island. ... > read full article

|

|

|

|

|

|

|

|

|

|

|

Brickwork: Historic Development, Decay, Conservation and Repairhttp://www.buildingconservation.com/articles/brick/brickwork.html

Gerard Lynch

Previously considered to be an inferior material to stone, brick construction was rarely used in Britain until the close of the Middle Ages. Gerard Lynch looks at its historical development over the last 600 years and its conservation and repair.

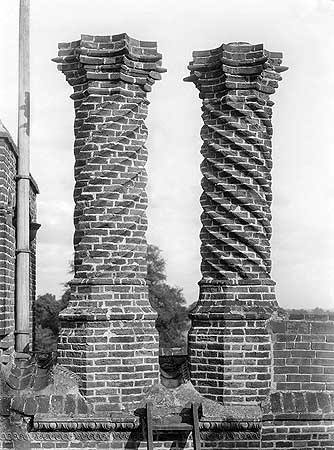

TUDOR BRICKWORK 1485-1603

The popularity of the material can be traced to the revival of brick-making in eastern England in the late 13th and early 14th centuries. This was a direct result of lack of local stone, an increasing shortage of good timber, and the influence of Europe where brickwork was used extensively.

By the Tudor period the brick-makers and bricklayers had emerged as separate craftsmen well able to rival the masons. From unsophisticated early work, brick building entered its heyday, rivalling stone in its popularity as a structural material.

Bricks were generally made on site in wood, heather or turf fired clamps by itinerant workers. Not only were standard bricks produced but also many in extravagant and elaborate shapes, epitomised by those that formed the spiral twisted chimney stacks for which the period is renown.

The Tudors further patterned their brickwork by inserting headers of over burnt or vitrified bricks into the walling. These dark surfaces ranging from deep purple to slate in colour, were laid carefully in quarter brick offsets in mainly English bond or English cross-bond, to form a diaper or chequered pattern within the predominantly red brickwork.

Tudor bricks were irregular in size and shape and therefore thick (15-25mm) mortar joints were necessary to even these out. The slow setting mortar was of matured non-hydraulic lime (often containing particles of the fuel used in its production), and coarse sand in a ratio varying from 1:2-1:5, the joints being finished flush from the laying trowel.

With the building of Hampton Court Palace, we have not only the seal of royal approval, but a monument to the achievement of brick in this period.

THE GEORGIAN PERIOD 1714-1830

The late 17th and early 18th centuries were a high point in the use of brick. Their manufacture was much improved, with blended clay, better moulding and more even firing which lead to greater consistency in shape and size. The colours of bricks changed in popularity from red, purple or grey bricks fashionable in the late 17th century until 1730, when brownish or pinkish grey stocks replaced the hot colours. These were followed in the mid 18th century by grey stocks, and, by 1800, the production of yellow marl or malm London stocks, which were closer to the stone colour desired for a classical facade.

Brickwork was generally of a very high standard, in mainly Flemish bond although header bond was also popular in the early 18th century.

Pointing was executed to a similar standard. As well as giving more protection to the weaker bedding mortar, fine detailing also helped to minimise the visual impact of the joints so that the classical details could be displayed more clearly. 'Tuck' pointing was the ultimate development in this quest.

A more expensive solution was to use 'gauged' brickwork popularised by Wren using a facade of fine, colour-matched bricks cut and rubbed to exact units, and laid in thin lime putty joints. However after 1730 this was considered too expensive and was reserved for window arches, aprons and other ornamentation only.

VICTORIAN BRICKWORK 1830-1914

This was a period of revivalism in domestic architecture and industrial building. The former seeking a return to 'medievalism' and other exotic building forms as a relief from the unspirituality of the Machine Age. The latter, for the infrastructure of factories, warehouses, railway bridges and so on, all largely met through the cheap use of bricks.

During this period, a greater number of bricks were made and laid than during all the previous periods. Brick manufacturing methods had improved in all respects including quality accuracy, regularity and in range of colours available. From the mid 18th century onwards the manufacturing process, like many others, was becoming mechanised. This enabled deeper clays to be used for pressing into dense bricks for use on civil engineering works.

With improvements in travel and communications, bricks could be transported over wide areas which removed the traditional local variations.

Improvements in the production of mortar also occurred during the late 18th century through the use of washed and graded aggregates, often with colouring. Also, the development of natural cements including Roman cement and other hydraulic limes, which set quicker and stronger, were vital to the speed of construction that the Industrial Age demanded. Portland Cement appeared in the mid 19th century.

Joints reduced to 0.3 inches (8mm) due to the accuracy of the machine pressed bricks and continued to be finished in various profiles. These were popular from the 17th century although the new 'weather-struck' and 'cut' style of joint became particularly popular.

A variety of face bonds were now used although, in the main, Flemish bond predominated domestically, whilst English bond was favoured industrially.

In all matters of brickwork, the Victorian desire for enrichment was readily achieved by the use of often garish polychromatic work, and the lavishing of ornamentation by detailing mass produced purpose moulded 'specials' or by gauged brickwork.

DECAY, CONSERVATION AND REPAIR

Before considering the most appropriate method of repairing brickwork, correct diagnosis of the cause of failure is vital.

Manufacturing defects in bricks can be the result of under firing or impurities in the clay used. These bricks decay more rapidly than better burnt bricks, especially with frost action. They can also act as a point of entry for moisture, which in turn will affect the whole wall, leaving it open to damage from frost and chemical action. Free standing walls, parapets and retaining walls are particularly vulnerable, and some judicious replacement may be necessary.

Poor Detailing can also contribute to failure through construction defects such as:

- Decayed bond timbers, joists, timber lintels, plates or bearers which have been embedded or built in to the masonry.

- The expansion of rust on corroding iron and steel structural members, wall ties or reinforcement embedded in the brickwork.

- Failure of arches and lintels from inadequate bearings, or abutments.

- Poor bonding and inadequate or even non-existent tying-in of brickwork. This can be due to a habit in the 18th and 19th centuries of 'snapping' headers leading to a wall of two skins, instead of one mass. Alternatively failure can occur at the junctions between walls, particularly where front and rear walls are insufficiently tied to the cross walls.

- 'Corbelling' (over projecting brickwork) and oversailing are especially prone to being insufficiently tailed-in to the main walling. They are also susceptible to water penetration due to inadequate, or non-existent protective weathering.

- Sulphate attack occurs when water is present with cement based mortars, producing slow steady expansion of sulphate crystals within the mortar or the bricks as the water evaporates. It can result in damage and even failure of the masonry. This is particularly common in unlined chimney stacks, where sulphates have been introduced by the burning of sulphur-rich fossil fuels. Where chimneys have been designed without bends, allowing rain straight down the flue, damp may appear on the chimney breast with a possible resultant salt problem. This can especially occur when the air is humid, or where the fireplace has been sealed without proper ventilation.

- Poorly designed parapet copings without damp proof courses, inadequate overhangs, and poor jointing techniques, which encourage damp penetration.

INDUCED DECAY

Remedial work to historic brickwork must be carefully selected after expert analysis and should always be kept to an absolute minimum.

- Consolidants should only be applied to decaying brickwork as a last resort. Although predictably effective on soft porous bricks their use is still in its infancy, and the long term affects of new techniques is less certain. The consolidated brick face may behave in a different manner from the base through thermal movement, resulting in eventual separation.

- Sealants may induce similar problems. By sealing the surface they may inhibit or reduce surface evaporation leading to a build up of moisture. This can result in concentrating evaporation in other areas where crystallisation and frost damage may be exacerbated. Sealants should only be used in localised areas to prevent problems such as the staining which occurs from water run-off from limestone dressings, where it may be used after removal of the deposits.

- The introduction of hard mortars is one of the most common causes of failure in historic brickwork, leading to a failure of the mortar and of the brickwork itself.

Inappropriate cleaning methods may cause substantial damage by removing not only the dirt but also the fireskin, leaving a pitted face. Rotary carborundum heads again, destroy the surface as well as dishing and scouring the 'arrises'. Such methods may actually accelerate re-soiling and rate of decay by producing a more textured surface.

Vegetation although often attractive, is generally harmful to older brick walls of traditional construction. Many types of ivy can cause serious damage to brickwork particularly if it is in poor repair, or constructed of soft, possibly spalling, bricks bedded in soft lime mortar where the pointing is defective.

If not carefully removed, ivy should at the least, be heavily controlled and never allowed to reach eaves level where it might block gutters and downpipes. In a strong wind, vegetation can also transfer additional wind-load, pulling out guttering, parapets, and even a chimney-stack.

Pigeons can also present problems, especially in city centres. Not only can they force up loose roof coverings, but they will block up gutters and downpipes with feathers, detritus and excrement, causing water penetration and consequent decay. The faeces rapidly deface the external (as well as internal) fabric, and may damage porous brickwork. Removal is difficult and expensive.

Control is therefore imperative, and can involve bird nets, repellent gels, poisons, traps and even shooting.

Recommended Reading

- · J Ashurst and N Ashurst, Practical Building Conservation, Volume 2: Brick, Terracotta and Earth, Gower Technical Press, Aldershot, 1988

- · TG Bidwell, The Conservation of Brick Buildings, Brick Development Association, Windsor, 1977

- · RW Brunskill, Brick Building In Britain, Victor Gollancz Ltd, London, 1990

- · N Lloyd, A History of English Brickwork, H Greville Montgomery, London, 1925

- · GCJ Lynch, Gauged Brickwork: A Technical Handbook, Gower Technical Press, Aldershot, 1990

- · J Woodforde, Bricks To Build a Brick House, Routledge & Kegan Paul, London, 1976

-

|

|

|

|

|

|

|

|

Air/Water Abrasive Cleaning of Stone and Brickwork

Nicola Ashurst introduces one of the most widely used techniques for the cleaning of masonry http://www.buildingconservation.com/articles/masonry/abrasive.html

The decision to clean an historic building is not one which should be made lightly, as cleaning can have significant physical and visual results. A period of detailed investigation must be undertaken to determine whether cleaning should be undertaken and, if so, the details of how this should be done. The nature and condition of all substrates must be understood, not forgetting pointing materials, as must the soiling to be removed. The latter may include atmospheric soiling, paint, limewash, metallic staining, anti-pigeon gel and graffiti. Each can require a different cleaning approach or at least modifications to the system selected for use elsewhere.

Every cleaning system can be used correctly or incorrectly. Poor cleaning should not be blamed on poor application alone as it is often the result of incorrect selection of a process. Glossy trade literature is no guarantee of correct selection. The design of a cleaning regime for an historic building is often deceptively complex, requiring specialist professional input.

The purpose of cleaning is to remove soiling, often a source of long-term deterioration to masonry, while causing little or no disruption of the masonry beneath. This can be difficult to achieve due to the intimate relationship between the stone and its soiling, as the soiling can be embedded deeply in between the surface particles.

Several published sources now exist which outline the basic constituents of various historic masonry materials and the susceptibilities of these to selective cleaning procedures. Previous experience must also come into play in assessing surface conditions and characteristics particular to the job at hand. The basic principles of any cleaning process must be determined if it is to be considered for use. Works should be undertaken by skilled supervisors and operatives from specialist masonry firms experienced in the cleaning of historic masonry.

Air abrasive cleaning systems are usually considered when soiling is not water-soluble and when, for reasons of site logistics or material incompatibility, chemical processes are inappropriate or less preferable.

A wide range of air abrasive techniques is currently available. These include a variety of machines, nozzles and abrasives from Hodge Clemco, Neokleen, Liquabrade, JOS and the suppliers of pencil abrasive techniques. Some larger scale equipment can be used in a very versatile and sensitive manner.

All air abrasive techniques operate by directing particles of abrasive onto the soiled masonry in a stream of compressed air. Cleaning is accomplished by impingement of the particles which dislodge or pulverise the surface layer of the masonry. This may be the layer of soiling or the stonework or brickwork to which it is attached. Most systems also involve the use of water, either additional to the air/abrasive stream or combined as a slurry with the abrasive. The main effect of the introduction of water is to reduce dust (both dry and wet abrasive systems clean in a similar manner), although the mist produced is still a health hazard.

Air abrasive cleaning techniques are most successful on surfaces of even profile and consistent surface texture and hardness. An air abrasive stream cannot on its own differentiate between the removal of soiling and the removal of masonry. Nor can it distinguish portions of masonry which are closer to the nozzle from those further away or areas of masonry which are softer. Damage to the masonry can only be avoided through the skill and ability of the operator to make the necessary adjustments in technique.

Air abrasive cleaning is usually most successful on plain stone surfaces of even hardness. Careful use can enable the technique to be employed on moulded and some carved stone surfaces. However it is difficult to successfully clean brickwork by abrasive means without any damage, due to the many variations in surface texture and hardness that are often present and due to the intolerance of many bricks to its impact. The removal of hard, traditional paints can rarely be achieved successfully from any masonry surface using air abrasives.

In the normal use of abrasive cleaning, two factors are of utmost importance; the velocity and the concentration of the particles which impact on the surfaces. These parameters are controlled by the pressure and volume of the air flow and the concentration of abrasive feed into the line. It is therefore not adequate to specify pressure alone. Important parameters will also include the size of the abrasive particle, its shape and its hardness. Commonly available abrasives for facade cleaning include aluminium silicate, calcium silicate, olivine and calcium carbonate. More specialist materials are also available, particularly for pencil abrasive equipment used by conservators.

Nozzle shape, nozzle size, rate of water flow and working distance must also be established.

It is usually best to determine the many parameters relating to abrasive cleaning on site when all soiling types, the degree of soiling and masonry conditions can be properly assessed. Specific advice such as recommended pressures and abrasive types cannot be given here as they are only a few of the many variables which must be determined, as already described. However, the following general principles can be applied:

- i) Smaller particles of the same abrasive type can be less damaging than larger ones, used in the same manner.

- ii) Harder abrasives can be more damaging than softer abrasives of the same size, used in the same manner.

- iii) A higher concentration of abrasive particles can be more damaging than a lower concentration, all other factors being equal.

- iv) Higher air pressure and volume can be more damaging than lower air pressure and volume, all other factors being equal.

- v) A closer working distance between the end of the nozzle and the masonry can be more damaging than a greater one, all other factors being equal.

- vi) Depending on how they are used, some small scale abrasive systems can be as or more damaging than larger scale systems.

- vii) Differences in technique will be required for plain and carved surfaces, sound and deteriorated conditions.

General recommendations cannot be made in relation to air abrasive cleaning, any more than with any other cleaning approach. Pre-contract on-site trials are always recommended for the cleaning of historic masonry. These should be overseen by an experienced professional who can observe and assess the effects of each procedure and produce a detailed specification for the works.

Recommended Reading

- · C Andrew et al, Stone Cleaning: A Guide for Practitioners, Historic Scotland, 1994

- · N Ashurst, Cleaning Historic Buildings, Volumes 1 and 2, Donhead, London, 1994

- · British Standards Institution BS 6270: Code of practice for cleaning and surface repair of buildings, Part 1, BSI, London, 1982

- · Technical Pamphlet 4: Cleaning Brick and Stone, SPAB (Society for the Protection of Ancient Buildings), London, 1994

- · ME Weaver and FG Matero, Conserving Buildings: A Guide to Techniques and Materials, John Wiley, New York, 1993

- · RGM Webster, Stone Cleaning and the Nature, Soiling and Decay Mechanisms of Stone, Donhead, London, 1992

-

|

|

|

|

|

|

|

|

Clay-tiled Roofs

Stephen Boniface and Tony Redman

http://www.buildingconservation.com/articles/claytile/claytile.htm

There is plenty of evidence that the Romans used clay tiles extensively on their properties. Although the use of clay tiles diminished somewhat during the Saxon period, by the 12th century there are records of clay tile use being encouraged particularly in place

of thatch for fire safety. The size of tile (10½" x 6½" x ½") was standardised in 1477.

In the early years the use of clay tiles, like many other building materials, was limited by cost. Nonetheless, for those who could afford it, clay tile was often the material of choice.

Another limiting factor was transport. Prior to the advent of mass transportation systems it was rare for clay tiles (or any other materials) to be transported any significant distance, typically not more than a day’s cart journey. Exceptions were made for the roofing of churches and the homes of the very rich, who often had access to clay fields and kilns further afield, and employed the labour, which made the costs much cheaper.

As a result the pattern of clay tile usage correlates closely with the areas in which clay and ‘brick earth’ are found, and it is perhaps not surprising to find that the manufacture of clay tile from the later medieval period was closely aligned to that of brick-making.

By the late medieval period a more stable social, economic and political climate resulted in an increase in wealth, generally enabling more people to afford materials such as brick, glass and indeed clay tiles.

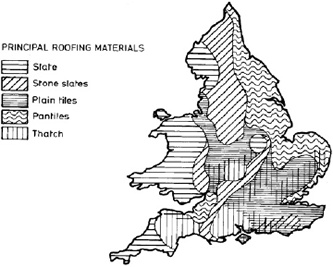

From the 17th century clay tile became the ubiquitous roofing material for large parts of the country where the raw material was close at hand – mainly the southeast and east of England and the Midlands.

Greater wealth in the 19th century, improved transportation and the introduction of taxation on fired building products such as tiles and bricks to fund the Napoleonic wars led to a reduction in the use of clay tiles and the increasing use of other roofing materials, particularly slate. However, it was the advent of the railway more than anything else that caused the roof map of England to change from red to grey. During the 19th century slate tended to be cheaper and thus it overtook clay tiles as the roof material of choice for the rapidly developing urban landscape.

During the 20th century mass-production of machine-made clay tiles resulted in a resurgence of clay-tiled roofs, particularly during the inter-war period. However, increase in competition from man-made tiles such as concrete tiles and man-made slate resulted once again in a downturn in the use of natural clay tiles. In more recent years homeowners have rediscovered the beauty of the material and there has been something of a resurgence in the use of handmade clay tiles.

The tile typically found throughout this period is the double-lap tile (one where the overlap between courses of tiles is greater than the length of a tile) but one should not forget the single-lap tile where the tiles interlock at edges only. Although today we are used to seeing the single lap tile in the form of concrete roofing materials, the history of single lap tiling goes back many centuries. The most common form is what we generically refer to as ‘pantiles’. These should not be confused with genuine Roman tiling, which in fact has not reappeared in any significant manner in this country since the 4th century AD.

The use of pantiles is not as widespread as clay tiling generally and it tended to focus on the eastern side of the country. Records indicate that pantiles arrived somewhere around the 17th century, with home-produced pantiles appearing from about 1700. Because the tiles were originally imported, their distribution tends to focus on the ports of the eastern seaboard. The exception is Bridgewater in Somerset, where pantiles were certainly established by the late 1750s and where a prolific pantile-making industry later emerged, supplying tiles throughout Somerset and the neighbouring counties.

MANUFACTURE

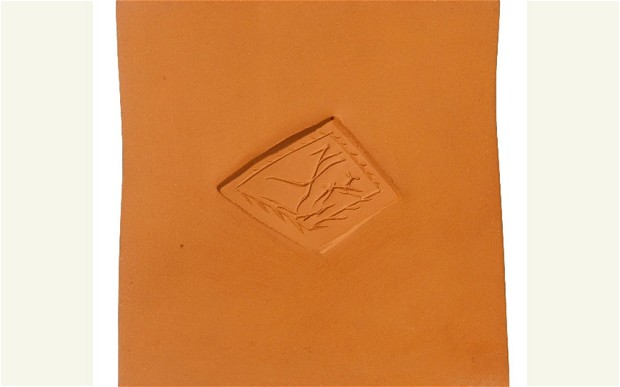

The manufacture of clay tiles is relatively straightforward. Traditional handmade tiles are a mixture of clay with aggregates rolled out and cut or moulded to simple rectangles (sometimes shaped) with two holes at one end for fixing. These are then fired in a kiln. Sometimes the ends were extended at right angles to form a nib, but the majority of clay roofing for many centuries was simply a baked clay rectangle.

Due to the firing, flat tiles would come out slightly convex and this added to their character. Uneven temperatures in the kiln and the nature of the hand-making process also contributed to variations in shape and form, and the quality of the clay resulted in rough and therefore textured surfaces. The colour would be determined partly by the clay and the mix of aggregates but also by the temperature and length of firing in the kiln.

Sometimes shaped tiles were produced and occasionally glazed tiles and pantiles can be seen. During the Victorian period there was much experimentation and occasionally one comes across multi-coloured examples. With modern machine-made tiles, dyes are added to bring greater consistency of colour.

FIXING

Plain clay tiles are laid in regular courses with each tile lapping two others, leaving approximately four inches exposed. The precise method of fixing depends on the nature of the tile itself. In the case of the more basic form of tile, simple tapered wooden pegs were pushed through the two holes at the top of the tile so that the tile could be hung over battens fixed horizontally across the tops of the roof rafters. The tops of the pegs would be trimmed flush to the surface of the tiles so that the next course would lie flat.

Lime mortar, sometimes with straw and other aggregates, would often be applied to the internal face of the tiles to fill the gaps and help improve the general fixing of the tile. This mortar fillet is often referred to as ‘torching’. On many roofs the pegs would be limited to only one per tile. Indeed, roofs can often be seen with no pegs at all, or at least pegs only in occasional courses. Although this can be due to the pegs rotting away, sometimes tiles were laid bedded in lime mortar with no pegs. In such

situations the fixing of the tile relied as much on friction and the weight of tiles above as on any torching or mortar bed.

If a tile had been made with nibs these would be used to hang the tile over the batten, and pegs would not be required. With modern tiling the nibs themselves have holes to enable nail fixing to the battens, although not every course is nailed in place.

As the use of slate increased, the need for nails to fix them also increased. The consequent increase in the production of nails resulted in their increasing use to fix clay tiles as well: nailing was quicker and avoided the need to trim the timber peg before laying the next course.

Today we find a wide variety of tiles available to us, including traditional peg tiles but also handmade tiles with nibs to facilitate fixing.

TYPICAL DEFECTS AND REPAIRS

It is often said that clay tiles have a limited life of up to 60 years or thereabouts. However, walking around the countryside you will often come across peg-tiled roofs that are several hundreds of years old, so this is clearly not a reliable guide.

The failure of the tile itself will depend on many different factors, including the original manufacture, the make-up of the material within the tile and its firing in the kiln.

Because tiles are much thinner in section than brick, they are less susceptible to variations in firing. Nonetheless, there will always be some tiles that are from the cooler parts of the kiln and therefore more vulnerable to early failure, particularly as a result of frost damage. That said, as a rule handmade tiles tend to have great durability and, if well-fired, tend not to be particularly vulnerable to frost damage. Only after many years will the best examples eventually weather, exposing the softer and more porous clay body below to frost damage.

Other factors which can influence the longevity of tiles (and, in fact, any roof covering) will be the orientation of a building, the steepness of the roof and indeed the microclimate around the building. Clay tiles are best used on roof pitches of 40° but some single lap tiles can be used down to 25° pitches.

Other more controllable factors include such matters as tree branches brushing up against the roof covering and dislodging or breaking tiles, climbing plants being allowed to grow over and into tiling to dislodge and damage it, and clumsy workmen treading on the tiles.

Due to the rough texture of a clay tile surface it is likely to harbour lichens and mosses. These plants should not necessarily be regarded as harmful. Although lichens produce acidic secretions and moss can hold moisture and lead to frost damage, they are unlikely to cause much damage. Indeed moss can provide a protective layer and lichens contribute to the characteristic colouring of tiled roofs. However, significant moss growth can increase the weight on the roof structure generally, and when it dies and rolls into the gutter it can cause quite serious gutter blockages.

If moss is to be removed, care should be taken. Simply pulling moss from the roof surface is more likely to cause damage than by letting it die naturally or by appropriate chemical removal means (biocidal treatment). However, care should be taken with chemical removal methods to ensure that the chemicals do not run down to the gutter and into the surface water system.

The defects that most often affect tiled roof coverings are in fact the sort of defects that affect all roof coverings: failure of battens (rot, woodworm etc); failure of the batten fixings (nail corrosion); deterioration of the tile fixings (rotting pegs, corroding nails or crumbling torching); failure of or defects to the roof frame; defects to perimeter details (soakers, flashings, etc); defects to roof details (valleys, verges, eaves, etc); and wind uplift.

Problems that can affect the tile surfaces, apart from those rare occasions when moss or lichen cause damage, are usually brought about by matters such as pollution, the premature failure of poor quality tiles, saturation from leaking pipes or drips from overhanging details such as TV aerials.

Frost damage can occur where moisture is retained on the surface and this sometimes happens at the laps. Sometimes localised frost damage can cause a tile to break at the head lap. Machine-made tiles are particularly prone to frost damage as the surfaces are more even and regular, enabling moisture to be trapped on the underside. Handmade tiles on the other hand have a natural variation which is both less moisture-retentive and more pleasing to the eye.

Other problems can arise due to poor laying in the first instance. Such problems include inappropriate detailing at verges and hips, poor setting and laying of the ridge and poor detailing of abutments such as chimneys and walls. Abutments need particular care. Local vernacular may dictate the use of tile creasings, or else mortar fillets, or lead. Lead flashings are usually the more reliable and mortar fillets the least. Whichever detail is used, lead soakers should always be incorporated between each tile to resist the passage of rainwater horizontally.

Another common failure with clay-tiled roofs is brought about by the failure of the fixings or battens due to rot or rusting. The battens often use sapwood, which is much more vulnerable to decay than heartwood. Pressure-treated battens should always be used for repair and replacement. If care is taken, many of the tiles themselves can usually be salvaged and reused. A word of warning, however: because peg tiles tend not to be pegged every course and therefore rely on friction and/or the torching, there is a risk of mass failure and slippage if a careless roofer steps onto the roof. Before attempting to repair a clay tile roof it is important to check the fixings below in case the attempt at repair itself causes more damage.

When repairing a tiled roof it is important to obtain as close a match as possible to the original in terms of texture and colouring. Non-ferrous fixings should be used to reduce corrosion risks. Any lime torching should be continued across new areas of work, and with the existing torching properly reinstated.

Most roofs can be satisfactorily patch-repaired rather than having to be completely stripped and re-covered. However, if complete re-covering is to take place, every attempt should be made to salvage the tiles and as a rule of thumb one would hope to salvage approximately 70 per cent.

Complete stripping and re-covering requires the new work to comply with building regulations, and this would often mean the use of a lining over the rafters beneath the battens and tiles. Such linings restrict airflow into the roof space, and the roof space then has to be positively ventilated or a modern breathable lining used.

It should be noted that where there is a double-lap roof covering, a lining is not strictly necessary for weathering purposes. Homeowners often attempt to line a roof because they believe it to be appropriate or perhaps to stop unnecessary draughts. However, attempting to line a roof from the underside (within the roof space) can lead to a number of problems. Because the lining is then not laid over the rafters it will direct any penetrating water into the eaves where it will cause rot and damage. Careful thought and installation is needed with regard to retrospective lining and it is best avoided.

In recent years there has been an increase in the use of expanded foam applications to the undersides of tiles. These are often marketed as providing a solution to insulation problems, securing loose tiles in place and reducing draughts. However, the use of such material should be viewed warily and it is suggested that such material should be regarded as a last resort only, particularly for historic buildings. Foam stuck to the underside of the tiles means the tiles cannot be salvaged for re-use at a later date. The practice also makes it very difficult to undertake patch repair in future because of the difficulty in getting individual tiles out. There is also a possibility of reducing the life of the tiles or slates if they are a bit porous, as it reduces the evaporative surface area: water absorbed when it rains will no longer be able to evaporate from the lower surface. The risk of frost damage is therefore greater.

Spray-on foams also perform poorly as a means of insulating roofs. The blocking up of ventilation and the lack of a moisture barrier can lead to condensation problems. Building regulations require a ventilation gap above insulation or a vapour membrane under the insulation, but with spray-on foams neither are provided.

From an aesthetic point of view these foams can also be a problem, as it is often difficult to prevent the foam spilling out between gaps in the tiles (particularly pantiles). Such foams are therefore a short-term form of repair that could increase the long-term cost of later work. If tiles are slipping it is better to undertake a proper repair.

Of course these negatives should always be balanced against the difficulty of access and perhaps the expected future lifespan of the roof. If the building is listed, however, such work would require consent and many conservation officers would probably refuse consent for use of such products.

Traditional clay tiles create beautiful roof coverings that are full of character due to the individual nature of the tiles. Provided they are carefully and properly maintained there is no reason to expect them to perform poorly. Many of the typical problems found can be resolved without loss of the tile itself. Before embarking on any work to a roof seek professional advice on what is required. If altering or extending the roof of a listed building, ensure the appropriate consent has been obtained.

|

|

|

|

|

|

|

|

|

|

Front Garden Legislation Myth or Reality

Over the last 18 months, there has been much talk on the changes imposed by the Government to the ways we pave our front gardens.

This is the gist of it… As of 1st October 2008 planning permission is required to lay traditional impermeable driveways that allow uncontrolled runoff of rainwater from front gardens onto roads, because this can contribute to flooding and pollution of water courses. However, householders will not require planning permission if they use permeable paving, or have sufficient drainage or soak away to ensure runoff from non-permeable surfaces does not go onto roads.

Basically, this is a great move. In times of heavy or sustained rainfall our drainage systems comes under extreme pressure. Catastrophic flooding in parts of the UK in recent years has demonstrated the distressing consequences of overloading the system and the importance of water management in our urban areas.

Permeable paving is certainly the best option environmentally, and the easiest choice when it comes to the new legislation. However not everyone has the right soil conditions for permeable paving and for it to work well, it really does need to be installed by a professional.

Whatever your choice – permeable paving or planning permission – there are plenty of products on the market that will suit every project.

|

|

|

|

|

|

|

|

News Release

Directory of Bricks - The Brick Directory - now on the web

13th May 2010

www.BrickDirectory.co.uk has been put together by Brick Man, Tim Bristow.

The Directory of Bricks is a comprehensive website of web links which helps Self Builders /builders/developers/renovators/architects get in contact with all brick manufacturers as well as brick merchants, importers and factors, brick services companies, builders merchants, roof tile and paver manufacturers. According to Tim Bristow ‘We are not selling anything just helping people choose the right red/buff/grey/orange/blue/black, handmade/pressed/wirecut/stock, reclaimed/rough/smooth textured, metric/imperial Brick from the 1,800 or so types available in the UK’. For inclusion in the web site send an E mail with logo and brief description to info@brickdirectory.co.uk

Ends

For further information, please contact

Tim Bristow, www.brickdirectory.co.uk Phone 07836 761541. E mail info@brickdirectory.co.uk or brickdirectory@aol.com

|

|

|

|

|

|

|

|

|

http://www.theselfbuilder.com/new-features/material-matters/bricks

The Brits have a fondness for bricks. Like Yorkshire pud and Sir Trevor McDonald, they have a special place in our hearts. It’s no surprise then that 80 per cent of new homes are clad at least in part using brick, and that it is still the most popular choice in the UK for the exterior of homes.

Think Victorian terrace housing, quaint church rectories and modern cul-de- sacs – bricks make up a large proportion of our built environment. Why then have bricks been frowned upon by recent generations of architects, spurned in favour of concrete or glass? Seen as too conservative by many and too closely associated with the past, perhaps? But as the projects featured in these pages show, bricks can be versatile, they can be daring and they can most definitely be cool.

Whether handmade or mechanically produced, the basic manufacturing process has remained the same for centuries. You dig the clay, mix and roll it, then dry it before it’s stored. On the day of production, water is added and the moist mud is banged into a wooden mould. Once turned on its head, the mould is prized from the clay and the bricks are dried to remove remaining water. Now ready for firing, they are stacked in the kiln and blasted at temperatures ranging from 900-1,200°C, depending on the type of clay. Checked for mistakes, packaged and placed in the stocking yard, the bricks are finally lorried away.

Nobody can call bricks boring. They come in an astounding range of colours and texture – indeed 38 varieties are produced from one Ibstock pit alone. The colour of a brick varies depending on the depth of clay used and the components added. To darken a brick, coal is added; to lighten it, lime can be used. There’s also a plethora of glazed bricks available. For texture, sand is commonly added to the clay to create a rough finish, while the use of oil or water when extracting the brick from the mould ensures a smooth surface. Other methods include dragging rollers indented with various patterns over the bricks and adding glass beads. Using these simple processes, blobs of mud are turned into an attractive and solid construction material. It’s now up to the architect to do the bricks justice and be creative with their designs.

SITE RULES

- Storage: inspect the bricks on delivery. Unload them directly onto a dry level area or scaffold and protect from the weather.

- Mortar: correctly proportion and thoroughly mix the mortar. Add nothing but clean water after this point and never use mortar after it has started to set.

- Uniform walls: to avoid patches or bands of different shades, use bricks from at least three packs at the same time and don’t place all the bricks from one pack in one patch of the wall.

- Protection: all brick walls must be covered during breaks in construction. Rain on recent brickwork can cause the mortar to change colour, or create lime stains, efflorescence and saturation. In cold, wet weather cover with a water-resistant material; in dry weather use hessian.

BRICK: A BRIEF HISTORY

The mud brick was invented between 10,000 and 8,000 BC making brick one of the oldest building materials known to man. The Mesopotamians developed the moulded brick in around 5000 BC, but the greatest breakthrough came with the invention of fired brick in about 3,500 BC. From this moment on, bricks could be made without the scorching heat of the sun and they soon became popular in cooler climates.

Brick was adopted in the Islamic world and in parts of India, South-East Asia and China – the Great Wall of China was constructed in brick during the Ming Dynasty (1368–1644). The Romans introduced brick building to Europe and it continued to dominate during the medieval and Renaissance period, with the red bricks of the Mediterranean and the austere brickwork of Northern Europe. The Georgians, Edwardians and Victorians all relied heavily on brick for their burgeoning cities.

Bricks crossed the Atlantic with Dutch and British immigrants and many early American skyscrapers are clad in brick or terracotta – an astounding 10 million bricks were used to construct the Empire State Building. It was used by some of the 20th century’s most famous architects including Le Corbusier, Frank Lloyd Wright and Louis Kahn, but towards the end of the century brick was perceived, unfairly, to be a cheap and uninspiring material. Brick lost out to stone, steel and glass, and became synonymous with uninspired developer-fare design.But with a new century comes a new attitude: brick is back with a vengeance. Despite competition from prefabrication and other new technologies, brick has regained a place in our hearts. Whether reclaimed bricks or their modern equivalents, architects and designers are once again recognising the qualities of these baked blocks of mud.

|

|

|

|

|

|

|

|

|

|

|

|

News Release

Directory of Stone in The Brick Directory - now on the web

18th May 2010

www.DirectoryofStone.co.uk has been put together by Brick and Stone Man, Tim

Bristow. The Directory of Stone (part of the www.BrickDirectory.co.uk Database) is

a comprehensive website of web links which help self

builders/builders/developers/renovators/architects get in contact with stone quarries

as well as stone merchants, importers and factors. According to Tim

Bristow ‘We are not selling anything just helping people choose the right

Cast, Portland, Slate, Granite, Marble, Ashlar, Sandstone, Limestone, Dressed Stone

from the 2,000 or so types available in the UK’. For inclusion in the web site send an

E mail with logo and brief description to info@brickdirectory.co.uk

Ends

For further information, please contact

Tim Bristow, www.DirectoryofStone.co.uk Phone 07836 761541. E mail info@brickdirectory.co.uk or brickdirectory@aol.com

|

|

|

|

|

|

|

Here are some basic tips for Bricklaying, and also for inspecting Brickwork and Bricklayers!!

As Written by REUSSIR LTD “The Premier Brickwork Contractor in South Wales" www.reussir.co.uk .

Laying

- Make sure the Mortar board is at least 600mm x 600mm in size, and does not have any nails in it. Ensure the labourer splashes it with water before putting any mortar on it. This will keep the mortar more workable for longer.

- Always cut your mortar down from the top of the pile with the blade of your trowel, and "ROLL IT", before lifting to place on the wall. There is nothing worse than watching a Bricklayer STICK his trowel into a pile of mortar, and lifting a huge lump up onto the wall, most of which falls off and smears the face of the brickwork, or if he is lucky enough to get it onto the wall, he will then have the problem of "overbedding", making more work for himself and putting more pressure on the wet course below, causing bricks below to tip or swim. I completely disagree with those that say it is "too slow" to cut & roll your mortar, It is far slower and more costly trying to correct roughly built brickwork.

- When you bed the brick, do so in a relaxed manner, without too much downward pressure on the brick, especially from the base of your hand, as this causes the brick to tip. You must also be aware of the brick laying correctly horizontally as well as vertically, this will prevent any "hatching & grinning". As the brick sinks into the bed caused by its own weight and a little pressure from you, any surplus mortar will spill out, as you run the sharp side of your trowel blade, along the face of the brickwork, keep the back of the trowel as close to the face as possible, before quickly turning it to catch the surplus mortar onto your trowel. If you`ve bedded correctly there will be only enough to use for the perp joint of the next brick you pick up.

- When jointing the perp of the next brick, make sure you do so in three quick movements. 1st is the centre of the brick end, then the two edges. Do Not "top & tail" the brick as this leaves a hollow joint, always make sure the joint is full.

- After you have finished the length of one course, always run the edge of your trowel along the back of the course collecting any mortar that has spilled out into the cavity face. This is very important, and make sure you catch as much of it as possible, and don't just cut it off, so it falls down the cavity, as this will dirty the ties and build up on any dpc trays etc.

"Remember, Correcting Brickwork is far more expensive, than building correct brickwork"

Brickwork can look good, but may be hiding a full cavity, poorly bedded ties, ties covered in mortar, dpc`s not bedded or split, other obstructions in the cavity etc, or many other defects.